Battery charge and discharge testers play a crucial role in preventive testing of UPS (uninterruptible power supply) units. These test instruments not only help ensure the reliability and stability of the UPS system but also effectively extend the battery life, thereby ensuring the safe operation of the entire power supply system. Equipment selection: Select an appropriate battery charge and discharge tester based on the type (e.g., lead-acid, lithium-ion, etc.) and capacity of the batteries used in the UPS system.

Jiujiang Jiuhong New Materials Co., Ltd., a company specializing in new materials manufacturing, places extremely high demands on the stability and reliability of its power supply in its production operations. As a crucial device for ensuring power supply, UPS (uninterruptible power supply) units play a vital role in the company’s production system. Therefore, conducting preventive testing on UPS units to ensure stable, safe, and reliable performance is one of the key measures Jiujiang Jiuhong New Materials Co., Ltd. takes to maintain the normal operation of its production system.

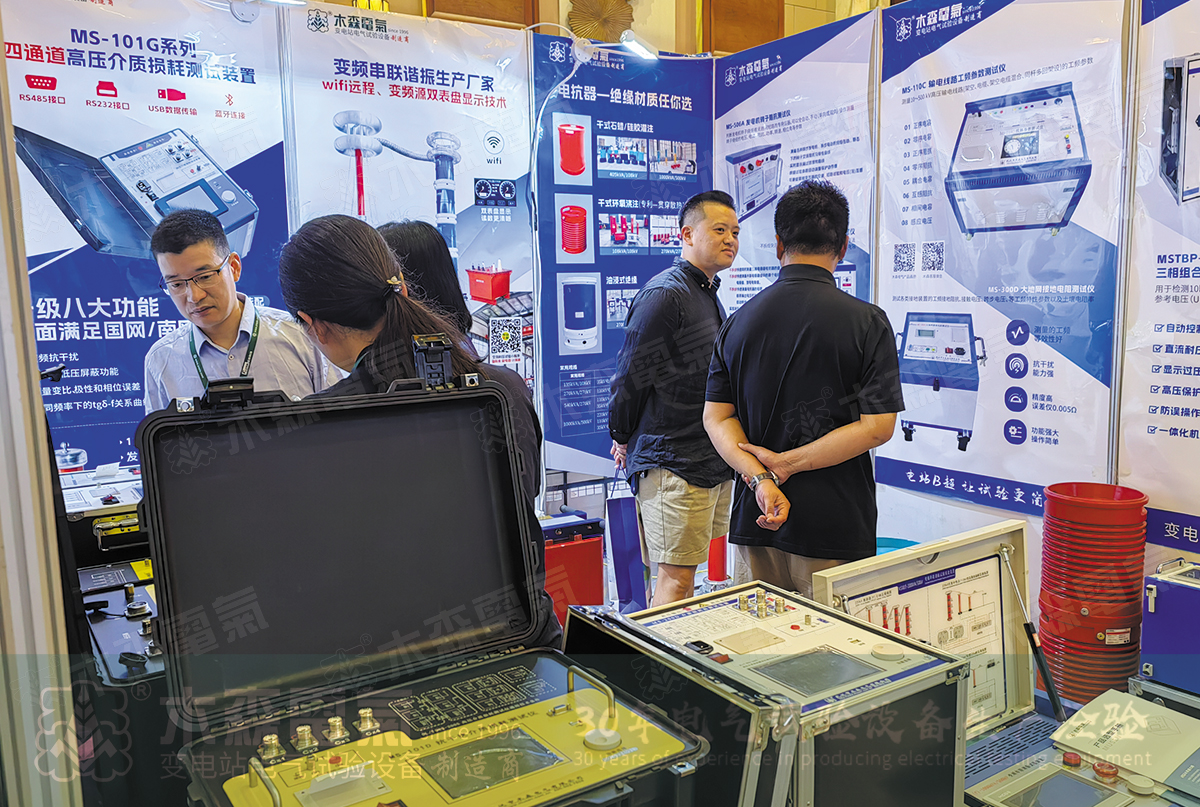

The commissioning project involved visual inspection, insulation resistance, and AC withstand voltage testing of six 35kV single-core cables (400mm² cross-section, 1.5km in length) at Jiangxi Jiujiang Jiuhong New Materials Co., Ltd.; visual inspection, dust cleaning, and battery charge and discharge testing of the UPS system (DC panel, batteries, and charging module). Upon receiving the testing assignment on June 19, 2024, a team led by Engineer Tan (Xiang Tan) immediately departed for Jiujiang, Jiangxi, arriving at Jiangxi Jiujiang Jiuhong New Materials Co., Ltd. at 2:00 PM that same day. The UPS batteries were located in two locations, and we conducted tests simultaneously. After the battery charge and discharge equipment was installed and testing began at the first location, I and a technician from the client company oversaw it while Engineer Tan (Xiang Tan) and Engineer Zhou (Zhou Zhiqiang) conducted battery charge and discharge tests at the second location. The test lasted 10 hours, and the preventive testing of the UPS system was completed at 3:00 AM on June 20, 2024. The equipment carried by our technicians on this visit was our MS-3982 and MS-3985 battery charge and discharge testers.

The successful completion of preventive testing of the UPS system at Jiangxi Jiujiang Jiuhong New Materials Co., Ltd. is one of the company’s key initiatives to strengthen equipment management and ensure the stable operation of its production systems. Through preventive testing, the company can promptly identify and correct potential safety hazards and fault points in the UPS system, improving the reliability and service life of the equipment and providing strong support for the company’s production operations.